DLS | Die Lubrication Solutions

Azienda giovane e dinamica è il partner d’eccellenza nel settore dello stampaggio a caldo dei metalli. Grazie ad una tecnologia innovativa e proprietaria, progetta e realizza apparecchiature per la lubrificazione degli stampi, miscelazione distaccanti e revisione macchinari.

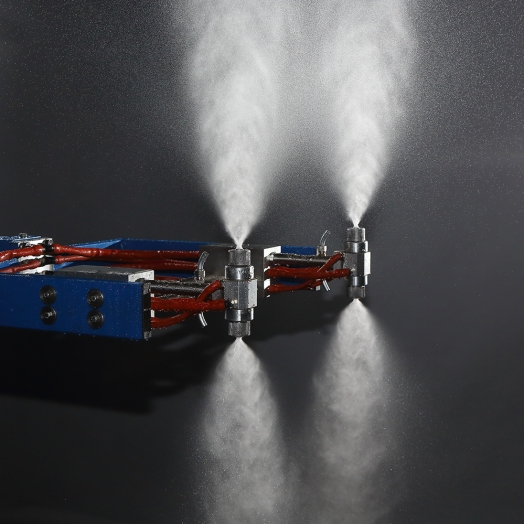

LUBSYSTEM | SERIES

MISCELATORI | DM